Anthony Browning is the Plant Manager at HELLA Electronics Corporation in Flora, IL, where he leads advanced manufacturing operations that blend innovation, automation, and community impact. Now, he brings that same forward-thinking vision—along with his commitment to Illinois, volunteerism, and years of service to this country—to IMEC as a member of the Board of Directors.

First Impressions

Growing up as the oldest of seven children in a small town, Anthony was no stranger to responsibility. His first job was at 14 years old working for his mother’s business growing 500+ tomato plants and selling them at local farmers’ markets. He had the opportunity to work alongside his father after completing high school, producing trash bags and other plastic bags; a factory job that made Anthony believe that manufacturing might not be the right path for him.

Luckily Browning did not give up on engineering quite yet. While still in high school, Anthony joined the Illinois Army National Guard out of Quincy, IL, initially working on electronics maintenance and repair, including chemical agent monitors, mine detectors, and radios. This hands-on work helped Browning towards his next path. “All of that helped grow me into someone that was able to troubleshoot, find problems, solve them, and identify different optimizations.”

More than ‘Just a Job’

Throughout college, Anthony continued his exposure to electronics not just through his studies, majoring in Electrical Engineering Technology at Southern Illinois University (SIU), but with his retail gig at RadioShack. RadioShack offered the creativity he didn’t find at his father’s factory, because RadioShack was a place people could, as Anthony put it, “put your creative hat on, buy components, build your own stuff. That was always intriguing to me.”

He had several options available to him after graduating from SIU, but one stood out among the rest: “HELLA intrigued me because one, it was a German company,” which he had experience visiting during his Army National Guard days, “but also it was in the automotive space, and I thought the automotive space would be exciting.” What HELLA also offered Browning that other manufacturers didn’t was a chance for him to be innovative and really test his skills. During his interviews, HELLA promised Browning, “some creative compacity on how to design processes and make improvements.”

A HELLA Innovative Factory

Two years in, Browning was assigned his first launch project of about $800k USD, taking it from concept phase to industrialization on the shop floor. “This is where I learned the most,” Browning noted. Then after starting his fourth year at HELLA, Browning overseay another new project of more than $4.5M USD. “We had other lines in other countries,” Anthony explained, “and we were launching it for the first time in the U.S. with new process technologies.” This launch included more than five trips for Browning to Germany, learning the processes and the line both as the Process Expert and the Manufacturing Engineer.

What was this project for? Manufacturing intelligent battery sensors (IBS) in the U.S that are utilized in the start-stop technology in modern vehicles. The IBS line is still producing today, 13 years later, among many other innovations Anthony has been a part of at HELLA since joining 18+ years ago (in 2007).

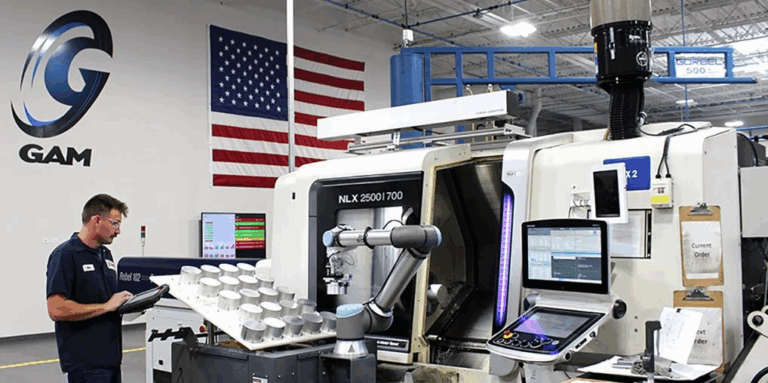

HELLA’s advanced integration of automation plays a significant role in these projects. “I’ve been to other plants,” Anthony remarked. “The level of automation in [our] plant is by far one of the highest I’ve been to. . . . We will have one assembly line that has anywhere between five to 20 robots in it doing mechanical assembly while linking to other systems for transport and testing.” The HELLA staff are behind the scenes, doing engineer- and technician-level work to keep those robots and automated systems running.

That level of automation is core to HELLA’s mission. “[Our] products are designed to be the cutting edge, the newest, better technology.” HELLA’s battery sensor, mentioned earlier, is the most advanced in the industry because of the way it is designed. HELLA’s processes, therefore, are uniquely designed to parallel that product innovation.

People and Community

While HELLA excels in automation and innovation, Anthony emphasizes that the company is just as committed to its people and its community. “They really focus on leadership training as well as creating a vision that inspires.” HELLA also wants to inspire their customers to go out, explore, contribute, and feel comfortable in their own vehicles.

Browning also emphasized the community impact a manufacturing plant has, “We are one manufacturing plant in a town of 5,000 people— what is our impact to the community?” That impact includes: Over $36 million worth of salaries and benefits to employees back into the community, as well as corporate donations to various causes, sponsorships to academic and athletic organizations, and local volunteer opportunities.

Anthony personally joined the local Cub Scouts troop in Flora and Louisville as their Cubmaster, and he acts as Assistant Boy Scout Leader. “Leading, coaching, and caring for the scouts at home or on an adventure truly recharges me.”

HELLA provides events and open houses for these scouts, including HELLA STEM Day with a STEM lab trailer from Scouting America. This trailer is decked out with 3D printing, laser engraving, video game design tools, programmable robots, and other educational games. After a meal is provided, HELLA even has a robot handing out candy to the children during the factory exploration tour where they can see automated guided vehicles moving around the factory floor!

A Vision for Manufacturing

Now Anthony Browning has joined IMEC as its newest Board Director. “It definitely drives me to build up and inspire others, and grow other businesses,” Browning concluded our meeting with. “We need to see that positive momentum.”